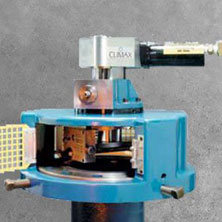

This OD-mount machine features a low-profile power module and centering/leveling plate for fast and easy setup. Mounting bell with wide-access windows simplifies gearbox adjustments. Facing diameters range from 0 to 12 inches (0 to 304.8 mm).

Two Mounting Bell Sizes

Two Power Modules

Optional Power Feed Module

Two Facing Heads

Optional Small Flange Adapter Plate

Quick and Easy Setup

Facing Diameter:

Milling Diameter:

ID Mounting Diameter:

OD Mounting Diameter:

Power Option:

This safe, versatile, and rugged OD Mount Flange Facer can machine flanges up to 12.5 inches (317.5 mm) in diameter without any attachments. Designed for the rugged challenges of the oil, gas and chemical industry, this machine has the versatility to machine seven different flange types, including RTJ and compact flanges. With feed controls located remotely for "hands-free machining" the FF1200 sets a new standard in operator safety while delivering up to 30% time savings on flange facing jobs.

Industry-Changing Safety

Flexible and Versatile

– Flat face

– Raised face

– Ring type joints (RTJ)

– Tongue & groove

– Lens ring

– Grayloc (hub profile)

– Compact flanges

… no reaching in means higher RPM machining

… adjust feed rate while machining – no need to stop, change direction, or replace parts

… start & stop feed while machining to machine to a shoulder

… easy machining of various types of materials

… a better surface finish

High Quality, Robust Design

Facing Diameter:

Milling Diameter:

ID Mounting Diameter:

OD Mounting Diameter:

Power Option:

Delivering superior performance and safety, this OD Mount Flange Facer can machine flanges up to 24.4 inches (619.8 mm) in diameter without any attachments. Designed to perform in the harshest of environments, this machine can handle flat face, raised face, RTJ, tongue and groove, lens ring, Grayloc®, and compact flanges. Like the other CLIMAX OD Mount Flange Facers, this machine delivers world-class operator safety with remote feed controls and a low-pressure safety interlock system that prevents unintended re-starts if air pressure is interrupted.

Industry-Changing Safety

Flexible and Versatile

– Flat face

– Raised face

– Ring type joints (RTJ)

– Tongue & groove

– Lens ring

– Grayloc (hub profile)

– Compact flanges

… no reaching in means higher RPM machining

… adjust feed rate while machining – no need to stop, change direction, or replace parts

… start & stop feed while machining to machine to a shoulder

… easy machining of various types of materials

… a better surface finish

High Quality, Robust Design

Facing Diameter:

Milling Diameter:

ID Mounting Diameter:

OD Mounting Diameter:

Power Option:

Unrivaled in capability for its size, this robust OD Mount Flange Facer can machine flanges up to 36.4 inches (924.6 mm) in diameter without any attachments. Like the other CLIMAX OD Mount Flange Facers, The FF3600 OD Mount Flange Facer machine comes standard with infinitely variable feed rates that can be adjusted while the machine is running, maximizing the user's ability to perform even in the most challenging environments within the oil and gas, power generation, and shipbuilding & repair industries.

Industry-Changing Safety

Flexible and Versatile

– Flat face

– Raised face

– Ring type joints (RTJ)

– Tongue & groove

– Lens ring

– Grayloc (hub profile)

– Compact flanges

… no reaching in means higher RPM machining

… adjust feed rate while machining – no need to stop, change direction, or replace parts

… start & stop feed while machining to machine to a shoulder

… easy machining of various types of materials

… a better surface finish

High Quality, Robust Design

Facing Diameter:

Milling Diameter:

ID Mounting Diameter:

OD Mounting Diameter:

Power Option: